Thermography

Let’s get visual

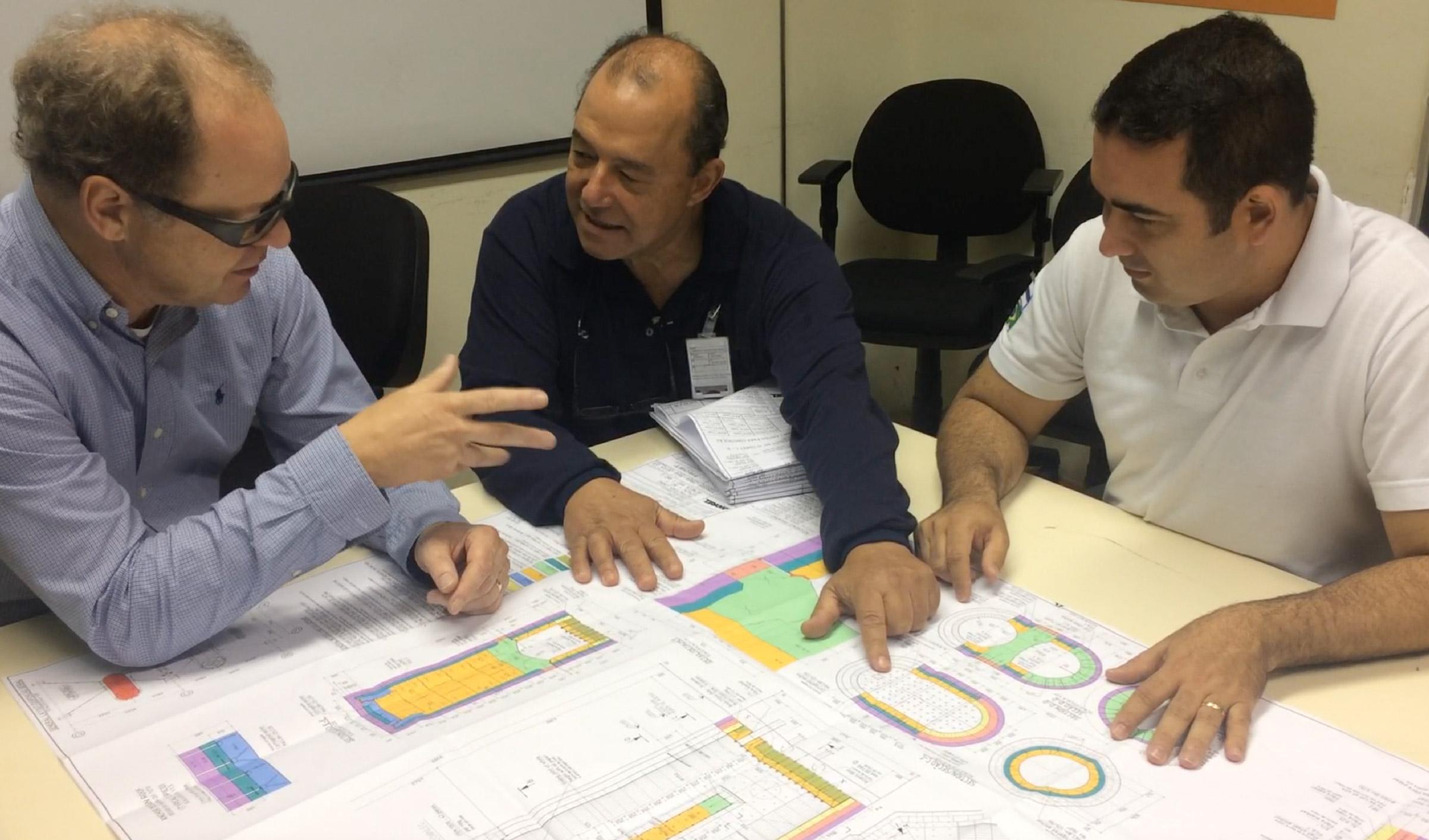

Reviewing and monitoring plants while covering all components can be tricky. Some weaknesses are not immediately visible to the naked eye or can be hidden behind insulation or steel panels. That’s why thermography, the imaging of heat radiation, is a great tool. With our high-resolution FLIR® heat imaging camera, we can detect any damage to your refractory lining, identify weak spots, or examine the thermal insulation of combustion chambers and pipelines. Thermography is highly reliable technology that allows precise monitoring of individual components. It can also be utilized during service early on in the planning of an upcoming audit to prepare for inspection downtime.